Print & Finishing Options

We offer a host of print and finishing options across a range materials starting with good quality white coated & uncoated papers, to more creative textured and self-coloured materials (see our “Creative Papers” section for more information on papers).

Quality litho and digital colour printing to exacting colour management standards, hot-foil blocking, cold foil, embossing and debossing, surface embossing, spot varnish and film lamination, more details below…

-

Litho & Digital Printing

Heidelberg B1 105 5col litho together with B2 HP Indigo digital printing enable us to offer high quality printing for large and small format bags, short and long run-lengths.

-

Hot foil blocking

Metallic and pigment foils offer a visually impactful means of applying your logo and other content across a range of materials. All types of foiling are environmentally friendly and all of our waste foil material is recycled.

-

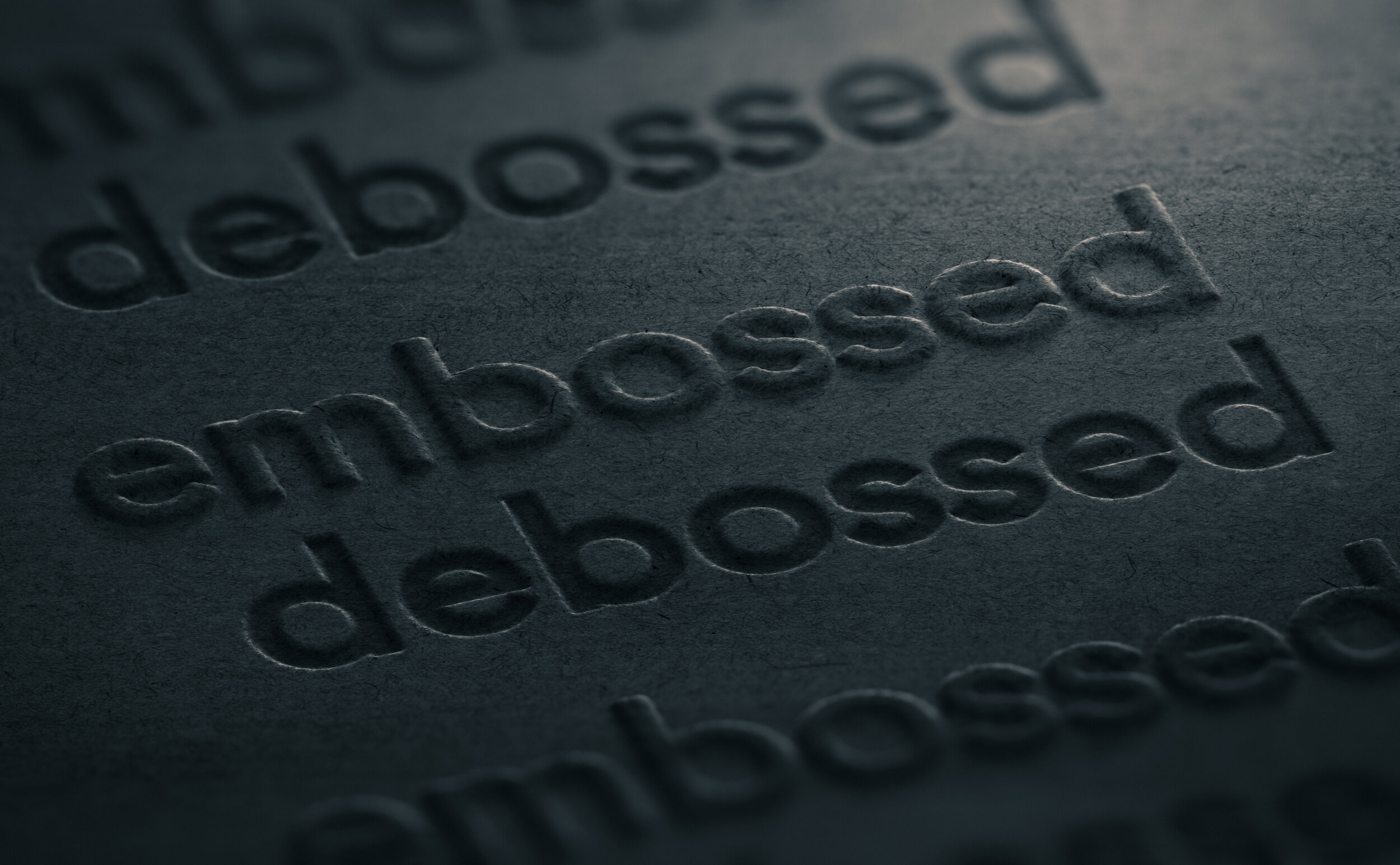

Emboss & deboss

Embossed: raised; debossed: indented. Commonly confused, each provide a subtle yet effective embellishment.

-

Surface Embossing Patterns

We can apply a textured surface to any material. In some scenarios this can offer advantages over materials textured at source, as we can printing onto a completely flat surface (enabling better printing quality) then apply a texture afterwards. Also a good option for applying texture after film-lamination has been applied.

Click here to see the range of patterns

-

Film Lamination

Lamination increases durability as well as enabling a range of finishes: gloss, matt, anti-scuff and soft-touch. At the material weights we use for bag production, laminated products are deemed recyclable by WRAP (2019 Waste and Resources Action Programme). In addition, we also offer “Cellogreen”, a cellulose based film that is also biodegradeable and compostable. See our “environment” page for detailed environmental information.

-

Spot Varnish

High gloss and matt varnish applied either directly onto the substrate or after film lamination has been applied.

-

Cold Foil

A highly effective variation on the traditional foiling process, cold foil is essentially a combination of foil and four colour print where both processes are applied inline. The printing press is adapted whereby the first two units apply metallic foil, then colour printing is applied directly on top, in perfect register, creating a metallic effect.

This means you can create any shade of foil. Furthermore, you can underpin a 4col image or graphic with foil, either in full, or highlighting specific areas, and the foiled areas will appear with a metallic shimmer. Very effective!